The followings are the recommendation in order to enhance the project

quality and performances:

|

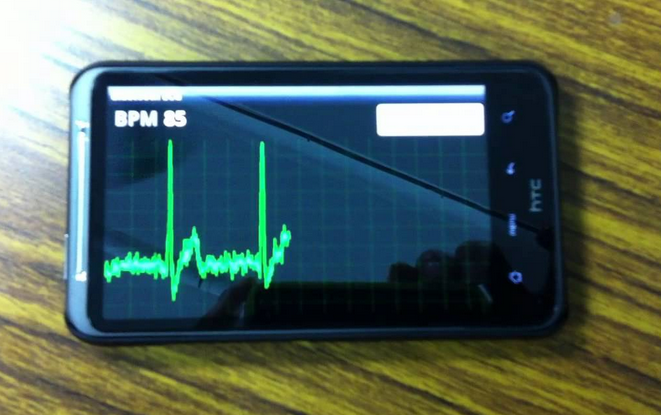

| ECG android system |

- The circuit should have more amplification and filtering to

maximize its output quality and tracking system.

- This project should connect into the android system hence the user can

see their own ECG continuously in smart phone application (in real time).

Hence, the result obtain can be share in the world wide which has internet

connectivity.

- The electrode sensor which is a cooper plate should attach together

with the Velcro strip to minimize the setting procedure.

- The electrode is exchangeable so that user can use the conventional

disposable ECG electrode which is cheap and easy to use.

- The circuit design can be improved from 2 electrode sensors to 6

electrode sensors. In other word, instead of using bipolar leads, this

project should be very precise and efficient by using precordial leads.

- The improvement of software part should be made by adjusting the software block diagram in LabVIEW. To do this, a research have to be done to study and exploring this software because the block diagram in this software must include filter block to minimize noise.

Although the project output was not in the same level of quality to be compared with conventional ECG

machine used by most of hospitals in Malaysia but the knowledge and principle

of this project is very useful for a medical electronics student and a fresh

medical engineer.